Unlocking Possible: Aftermarket Parts as a Cost-Effective Remedy for Machinery and Heavy Equipment

In the ever-evolving landscape of equipment and heavy tools maintenance, the utilization of aftermarket parts has become an engaging different worth discovering. These parts, often neglected for original devices producer (OEM) components, present an affordable remedy that necessitates focus. While the concept may elevate brows among reactionaries, the benefits that aftermarket parts supply in regards to price financial savings, high quality, and performance are not to be taken too lightly. As markets seek ways to optimize and maximize operations effectiveness, the possible opened by aftermarket parts positions interesting possibilities that could improve well-known techniques and produce significant advantages.

Price Cost Savings and Value Suggestion

The price savings and worth suggestion of utilizing aftermarket components for equipment and heavy tools are considerable elements that add to operational performance and economic practicality in various sectors. By going with aftermarket parts over initial devices supplier (OEM) components, services can recognize considerable expense savings without jeopardizing on quality or efficiency. Aftermarket components are frequently a lot more competitively priced than their OEM equivalents, allowing companies to lower repair and maintenance expenditures while still ensuring the appropriate performance of their machinery and tools.

These parts are widely offered and offer a broader choice compared to OEM parts, providing businesses with higher flexibility and convenience in sourcing the parts they require. Furthermore, aftermarket components are known for their high top quality and integrity, conference or even exceeding industry standards in lots of situations.

High Quality and Compatibility Guarantee

When thinking about the utilization of aftermarket parts for machinery and hefty tools,Emphasizing the extremely important significance of high quality control and compatibility verification is necessary. Making sure that aftermarket parts exceed or fulfill industry standards for top quality is essential to preserving the optimal efficiency and longevity of the equipment. Quality assurance procedures, such as strenuous testing procedures and qualifications, give confidence to equipment owners that the aftermarket components will certainly operate dependably and effectively.

Raised Schedule and Alternatives

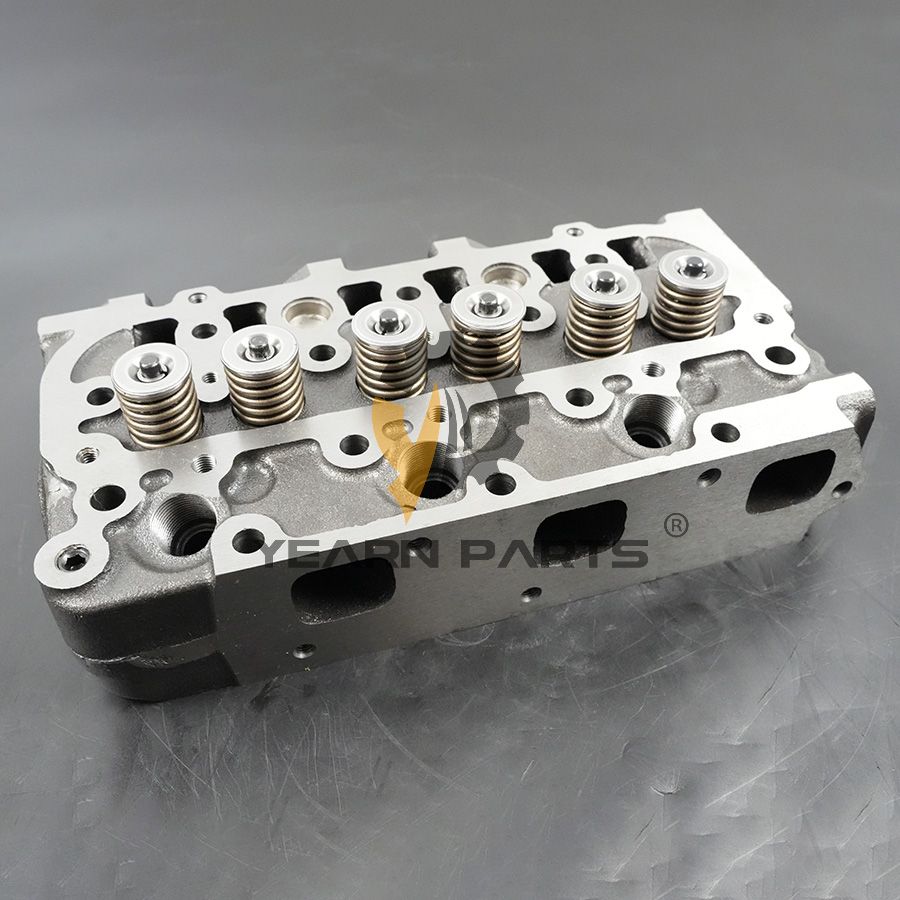

With a broadening market and growing demand, aftermarket components for equipment and hefty tools are currently providing boosted accessibility and a wider series of choices to deal with the varied demands of devices owners. This surge in availability is driven by the aftermarket parts industry's dedication to fulfilling the certain needs of numerous equipment brand names and versions. Tools proprietors can currently access a vast array of aftermarket components, ranging from engine elements to hydraulic components, electrical systems, undercarriage elements, and much more.

Additionally, aftermarket components suppliers are constantly expanding their product lines to consist of parts for a wider series of equipment and hefty tools, making certain that proprietors can find appropriate replacements regardless of the devices type or design they have. This enhanced schedule and selection of aftermarket components equip equipment owners to make affordable decisions without compromising on quality or performance. Therefore, they can efficiently keep, fix, and upgrade their equipment with confidence, recognizing that aftermarket components use a reputable choice to OEM elements.

Efficiency and Longevity Perks

Enhancing machinery and hefty equipment with aftermarket components brings significant performance and sturdiness advantages to tools owners. Aftermarket parts are commonly made with developments in innovation and products, offering boosted efficiency contrasted to initial equipment producer (OEM) parts. Upgraded elements can lead to boosted power, performance, and total machine capabilities, resulting in enhanced efficiency and operational efficiency.

Furthermore, aftermarket parts are often engineered to be more long lasting and resilient than their OEM equivalents. This boosted longevity can convert to lowered downtime for repair and maintenance, inevitably conserving tools proprietors useful time and cash. By purchasing aftermarket parts understood for their toughness, machinery and heavy equipment can withstand harsh operating problems and hefty work with higher strength.

In significance, the efficiency and sturdiness benefits of aftermarket parts add dramatically to maximizing the performance and long life of equipment and heavy equipment. Equipment proprietors stand to obtain an one-upmanship by leveraging aftermarket remedies to boost the general efficiency and click this site longevity of their possessions.

Sustainability and Ecological Impact

The utilization of aftermarket components not just enhances the performance and longevity of equipment and heavy equipment however also plays a crucial function in dealing with sustainability issues and reducing ecological impact. By choosing aftermarket components, industries add to the reduction of waste generation since these components are typically sourced from recycled materials or with remanufacturing procedures. This technique straightens with the principles of a round economic climate, where sources this are used successfully, and waste is lessened.

Additionally, aftermarket parts can prolong the lifespan of equipment and equipment, minimizing the regularity of substitutes and consequently lowering the you could check here general carbon footprint connected with producing new equipment. In addition, the manufacturing of aftermarket parts usually involves much less power usage and less emissions compared to producing original devices maker (OEM) components - Bobcat Aftermarket Parts. This shift to aftermarket parts supports eco-friendly practices by promoting reusability and source preservation within the commercial field. Inevitably, the assimilation of aftermarket components right into equipment repair and maintenance is a sustainable method that benefits both companies and the atmosphere.

Verdict

In verdict, aftermarket components supply a cost-effective solution for equipment and hefty devices by providing expense savings, high quality assurance, raised availability, performance advantages, and sustainability benefits. These parts not only offer a viable option to original equipment supplier parts however likewise add to the general efficiency and long life of equipment and equipment. Embracing aftermarket parts can cause significant price financial savings and boosted efficiency, making them a useful choice for businesses wanting to maximize their resources.

By choosing for aftermarket components over initial devices manufacturer (OEM) parts, businesses can recognize considerable cost financial savings without compromising on quality or efficiency (Bobcat Aftermarket Parts). Equipment proprietors can now access a wide array of aftermarket parts, varying from engine elements to hydraulic parts, electric systems, undercarriage parts, and much more

In addition, aftermarket components makers are continuously increasing their item lines to include components for a more comprehensive range of machinery and heavy devices, making certain that owners can find appropriate substitutes no matter of the tools kind or version they possess. Aftermarket parts are typically made with advancements in technology and materials, offering improved performance compared to original devices producer (OEM) parts. Furthermore, the manufacturing of aftermarket components usually entails much less power intake and less exhausts contrasted to making initial tools supplier (OEM) components.